Nitrogen Gas

Generating System

< PSA System >

DAISHIN / MAYEKAWA Nitrogen Gas Generating System

It can remove oxygen and carbon dioxide gas and water in the atmosphere by the method of PSA in a short time. It can provide a stable supply of high purity nitrogen gas. Among the different variations, we propose an optimal device to the structure of the ship.

※What is the PSA system?

It stands for Pressure Swing Adsorption system. By utilizing special carbonate molecular sieves, nitrogen gas is produced by removing oxygen from the pressurized air.

Main Features

- Low electricity consumption.(about 2/3 of membrane type)

- Compact designed units by the adoption of high performance adsorbent.

- Quiet design

- Wide range of purity of nitrogen gas between 95% and 99.99%.

(If higher purity of nitrogen gas is required)

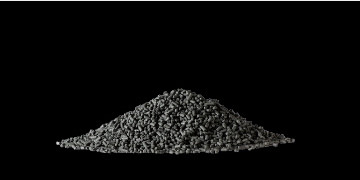

High performance adsorbents

New carbon-based adsorbent with special phenolic resin as a raw material.

MSC(carbon molecular sieve) of a high-performance synthetic polymer as a raw material, is characterized as follows.

- ・Cylindrical with 1mm diameter and 2 ~ 3mm length.

- ・It has excellent homogeneity, since made from synthetic phenolic resin.

- ・It can be separated and purified nitrogen gas with high efficiency, since has a unique pore structure.

- ・Excellent durability and wear resistance.